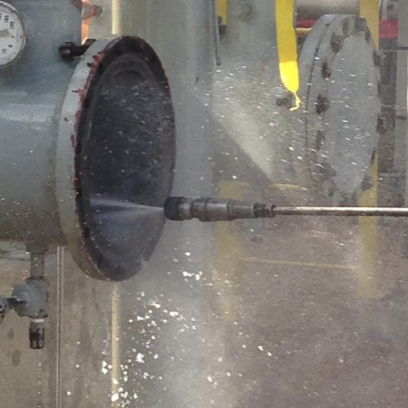

“Sierra Chemicals was our first call when we needed help with a plate and fin exchanger that was plugged up. Our exchanger was completely clogged with a mixture of mol sieve dust and heavy hydrocarbons. For us to replace this exchanger, it would involve waiting for 7 months just for the parts to be manufactured at a cost of $500,000, plus an estimated loss of revenue of over $4 million with the plant shutdown it would entail.

Sierra worked with us to come up with a cost-effective solution that was tailored to our needs. Sierra had the system cleaned & flushed with methanol and turned back over to us in just 12 hours. Thanks to Sierra’s chemical cleaning, we were able to extend the lifespan of the exchanger and avoid a costly unplanned shutdown.”

– Senior Engineer

Major Midstream Facility, Williston, ND